Northern Powergrid engineers test arc rated GORE-TEX PYRAD® products

Reference Case

Leading companies increasingly recognise the benefits in investing in durable, comfortable and superior quality personal protective equipment (PPE) for their employees, particularly those working in potentially hazardous environments and in tough weather conditions. Northern Powergrid recently received feedback when its electrical engineers put their newly issued arc rated GORE-TEX PYRAD® jackets, salopettes, hoods and coveralls to the test during some of harshest storm conditions the UK has experienced for many years.

Northern Powergrid manages and maintains the electricity distribution network that powers everyday life for more than 8 million people across 3.9 million homes and businesses in the North East, Yorkshire and northern Lincolnshire. Its network of 63,000 substations and 60,000 miles of overhead power lines and underground cables safely delivers the electricity bought from energy suppliers. As a 24/7, 365 business, it’s there for customers through a team of some 2,700 people including around 1,300 frontline utility workers. In an evolving energy industry, Northern Powergrid and its people have a key role in creating and managing future energy systems that increasingly interact with customers and smart and low carbon technologies.

Electrical Workers Needs

Utility and electrical engineering offer challenges to its workers, especially those who have to work daily in changeable weather conditions but with the potential risks of the thermal hazards of electric arc flash.

Colleagues had remarked that the traditional wet weather PPE provided was bulky and heavy, that it was often too warm to wear during strenuous work and that it took a long time to re-dry at the end of a shift. Arc rated PPE needs to offer the highest levels of protection for utility workers against the potential daily risks of thermal hazards from an electric arc, without weighing down the end user with garment bulk. When working with live electrical systems there is always a remote risk of a worker being exposed to an incident involving a high temperature arc flash. Such incidents are extremely rare but nevertheless, companies need to protect their engineers by procuring Class 2 arc rated protective workwear with flame retardant properties. Garments which are Class 2 arc rated refer to the protection level of European Norm IEC 61482-1-2 (Box test), which stands for: protective clothing against the thermal hazard of an electric arc.

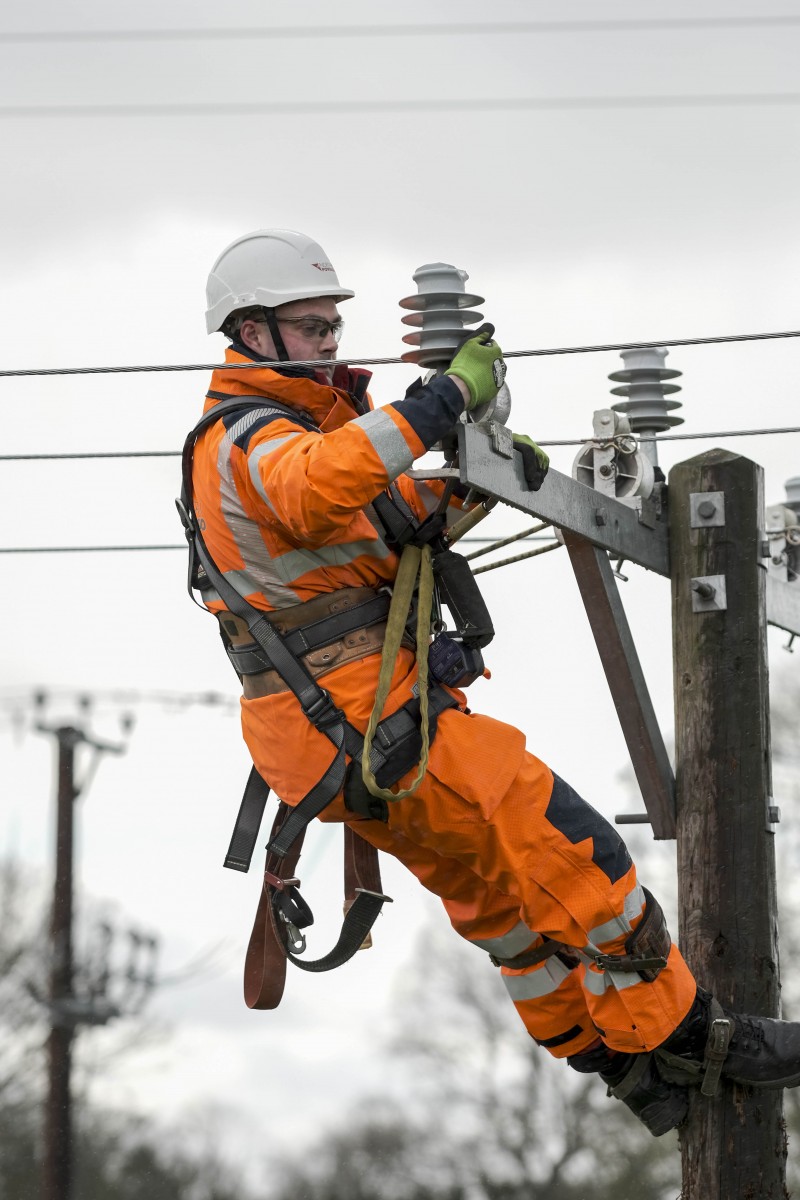

For wearer comfort, garments need to be light to wear – wet or dry – so they are able to be worn for long shifts, in changing weather conditions. Protective garments also need to be robust and durable to not only last, which makes them more cost effective but also help the environment because they have a longer wear cycle and need replacing less often. For engineers working at height, up on poles or platforms, PPE should enable free movement, be flexible and offer high visibility for safety.

In addition, Northern Powergrid workers may face a difficult journey before they start work to reach their assigned repair site. Sometimes, they are required to move through difficult terrain to locate a fault on the power network so clothing needs to be robust enough to protect the workers from more general hazards.

For these roles, the correct balance of protection, ruggedness, comfort and ergonomics is an essential prerequisite for the workers’ PPE.

Northern Powergrid’s PPE Developments

Sean Johnson, a Safety Engineer at Northern Powergrid for 39 years, responsibilities include legal standards, policy, accident investigation, risk assessments and operational controls.

Back in 2009, Sean was part of a project team at Northern Powergrid which analysed the protective characteristics of arc flash safety clothing through a study of the potential risks for operatives working within the network. This study helped determine what levels of protection were needed for the different roles and risks a frontline utility worker could face as part of their job.

Using this information, Northern Powergrid commissioned a number of key industry players to develop a specification that would answer protection requirements. The working group found solutions that would provide comfort, protection and the correct corporate palate, which at that time was black and red. Following wearer trials and agreeing the specification, a competitive tender was won by J & K Ross, UK based specialists in PPE, Health & Safety Clothing distribution. In 2013 Northern Powergrid clothing sets for the 1,300 strong workforce were produced and distributed in one logistical hit and within one month all colleagues had all the protective garments they required to work safety and with complete protection. The clothing sets contained a previous generation of GORE-TEX Heat and Flame wet weather garments arc rated Class 2 (Box test). One layer of clothing provided in excess of 8 cal/cm² of protection, while two layers would provide in excess of 30 cal/cm² of protection based on both the Arc Thermal Performance Value (APTV) and ELIM Value.

Recent Developments at Northern Powergrid

In 2020, Northern Powergrid set about developing new products with Gore, J & K Ross and Gore’s licenced manufacturing partner MSA Bell Apparel. Together, they started exploring how the new arc rated GORE-TEX PYRAD® technology might be adopted by the Northern Powergrid team.

Arc Rated GORE-TEX PYRAD® product technology is a waterproof, windproof and breathable multi-norm compliant lightweight flame-resistant fabric. In the case of an arc flash exposure, the fabric stops flame propagation by rapidly reacting and forming a stable insulating protective shell of carbonaceous char with the face fabric (without melting or dripping) Its functional protective mechanism reduces the transfer of heat to the wearers skin and blocks the heat flow from the arc flash exposure making it suitable for an end user who requires protection levels to protection levels to IEC EN ISO 61482-1-2, arc rated to Class 2 (Box test).

Based on arc flash testing according to IEC 61-482-1-1 (open arc test), it offers an incident energy limit value (ELIM) of 42 cal/cm² of protection. Additionally, it is electrostatic dissipative and protects against liquid chemicals. Being up to 50% lighter than other Arc rated Class 2 fabrics in the market, arc rated GORE-TEX PYRAD® product technology is the only solution that offers the perfect balance of multi-norm protection, comfort and durability.

The Procurement Project Team

The vital importance of multi-protection PPE for Northern Powergrid colleagues was appreciated and understood by the working group. Severe weather protection, as well as the correct electric arc protection were top of mind.

Northern Powergrid identified it would need severe weather arc rated jackets, hoods, salopettes and a number of coveralls. Northern Powergrid assembled a wearer trial team which was made up of lines people, jointers and fitters. Working with the wearer trial team J & K Ross and MSA Bell Apparel listened to their feedback and requests and modified designs. Working closely with the GORE workwear team, GORE-TEX PYRAD® fabric technology was supplied in hi-vis orange. This ensured workers could be safely seen and identified as Northern Powergrid at distance – as other outdoor workers typically wear yellow and had the additional benefit that flying insects wouldn’t be attracted to the orange.

GORE’S manufacturing brand partner, MSA Bell Apparel, produced small quantities of design prototypes in their UK facility using GORE-TEX PYRAD® fabric, which were fully tested in GORE’s state-of-the-art laboratory testing facilities to ensure they were fit for purpose.

The trial team feedback resulted in design improvement, specific to the worker’s needs, such as a request for a Nelson pocket on the jacket which was large enough to hold a switching book. End users also requested changes to the jacket cuffs so gauntlet gloves could easily be put on over these. A traditional jacket cuff proving too wide to allow this to easily happen. This resulted in a narrower cuff being incorporated into the design of the new jacket.

Only when all members of the procurement project team and the wearer trial team were fully satisfied with the final and fully tested design did the MSA Bell Apparel go into full production.

Chris Ross explained how he welcomed the introduction of GORE-TEX PYRAD® fabric technology to the market: “When it was launched, PYRAD was very much needed in the electrical PPE sector. It’s a brilliant fabric because it’s not stiff or heavy and provides complete comfort and protection.”

In July 2021, MSA Bell Apparel supplied the new issue of hi-vis orange jackets, hoods, salopettes and coveralls to J & K Ross for distribution. Industrial laundering company, phs Besafe supplied unique bar codes which were then fitted by J & K Ross to every garment and these were then assigned to every Northern Powergrid industrial colleague. The bar-coding system allows phs to collect garments from depots, professionally clean and then return them directly back to the individual’s locker.

When it was launched, PYRAD was very much needed in the electrical PPE sector. It’s a brilliant fabric because it’s not stiff or heavy and provides complete comfort and protection.

Harsh Weather Calls for Robust Protection

With 47 years of working at Northern Powergrid , Training Engineer David Reed is perfectly qualified to explain why quality PPE provision is required to cope with the reality of outdoor utility work: “Whatever weather comes we just have to be out in it and working. Weather can be an absolute enemy to utility workers.”

Outdoor electrical workers are not afforded the luxury of staying indoors when the weather turns harsh. Indeed, extremes of weather, such as heavy storms, gale force winds, hale, snow and driving rain are a reality during autumn and winter months for those working on the front line to maintain, repair or upgrade Northern Powergrid’s electricity network.

The winter of 2021/2022 saw the UK – and Northern Powergrid’s operating area - exposed to a series of severe and disruptive storms that provided real life testing for the newly supplied GORE-TEX PYRAD® jackets, salopettes and coveralls.

The multi-protection, multi-norm garments needed to do the following:

- offer Class 2 arc flash rated protective properties to IEC 61482-1-2

- provide flame resistance

- contain antistatic properties: EN 1149-3/-5

- provide protection against rain: EN 343 class 3/3

- dry out overnight and be ready to wear for the next day

- offer breathability so the inside of garments remained dry/ comfortable

- be comfortable to wear so that the garments are worn correctly by end users

- offer high visibility: EN ISO 20471 HI-VIS orange, which would not fade after laundering

- be durable to withstand the daily challenges of the utility worker

Questionnaire Feedback

After several months of using their GORE-TEX PYRAD® garments, during some of the most extreme storm conditions to hit the UK for several years, Northern Powergrid’s frontline teams were asked to give their feedback via a questionnaire, distributed by team leaders. The job roles of respondents included: jointers, apprentice fitters, faults coordinators, field engineers, apprentice cable jointers and overhead lines people working in the north of England covering North and West Yorkshire, Teesside and Humber regions.

Key findings include:

- Half of the respondents regularly work with a harness and at height; of these workers all stated they felt sufficiently warm whilst wearing their garments, 58% felt pleasantly dry and 83% found the ergonomic fit of the garment to be very soft and very flexible.

- The entire cohort, 100%, stated that the garments kept them dry.

- When considering the weight of their protective garments 19% found them to be very lightweight, 81% found them to be a comfortable weight.

- When asked how the GORE-TEX PYRAD® garment compared to their previous garment when worn in heavy rain, 84% found the new garments better, 16% found they functioned at the same level.

- Survey participants were asked to state how long their garments take to dry after being exposed to rain all day. 54% stated it took less than six hours, 30% considered it took less than 12 hours, (with 16% of the cohort unsure of the exact drying time.)

Within the questionnaire, Northern Powergrid team members were asked to state in their own words which design features they most valued about their GORE-TEX PYRAD® garments. The majority of responses related to the lightweight quality of the jacket and the fact they were totally waterproof. Additional responses referenced the design and position of the pockets, that the elasticated cuffs on the wrist help to stop the jacket from rising up when stretching. They also mentioned that the new cuff design meant putting on gauntlet gloves was now easier and that the hi-vis orange colour means that flying insects were not attracted to the jacket.

Individual Interview Feedback

In addition to the quantitative feedback from Northern Powergrid’s workforce, one to one interviews were conducted to gain qualitative insights from the end users.

For apprentice linesman Callam Hickling, 25, the toughest part of his job is being out in bad weather climbing poles with leg garter spikes and a harness, for him, good fitting kit is really important. He explains how he finds working outside in the elements: “Heavy wind and rain doesn’t help. Windchill can be an issue because its cold and windy when you are on top of a pole a good 10 metres, if not more, from the ground.”

Commenting on his GORE-TEX PYRAD® jacket and salopettes Callam said: “I feel confident that the kit is going to protect me in bad weather. A while ago I worked for 16 hours in the rain and I was bone dry. The kit is dry by the next day for when I needed to next use them.”

When PPE doesn’t perform and isn’t fit for purpose, the impact on the wellness of utility workers should not be underestimated. Jordan Ellis comments: “If I had gotten wet during those long 16-hour days recently would not have felt the best or particularly good the next day. I would definitely have been full of cold and would have been aching. Because the kit kept me warm, I think this helped my body so I could go out again the next day in the lashing rain and storm.”

Fellow apprentice linesman Bayley Rowlands, 22, noticed the difference in weight between his new kit and his previous issue: “They are really good being waterproof and they don’t let rain soak in. They are lighter than the old kit aswell and I do feel the difference in weight. The jacket fits really well and there isn’t any constriction of moment.”

Jordan Ellis, 22, evaluated his new GORE-TEX PYRAD® jacket and salopettes during a major incident before Christmas. Jordan explained the first time he really put his new kit to the test: “During Winter last year, I was wearing both my jacket and the salopettes and I had to climb up a pole because we had a conductor down and it was chucking it down with rain. It was dark because it was 7.30 in the evening by then and still raining. I had everything done up on my kit. I had thought I’d be freezing cold in my kit but I was ok, I got warm. I was completely dry inside and I was really impressed that the kit was this good. Underneath it felt absolutely fine, bone dry, after a long 16-hour shift.”

Training Engineer David Reed, 63, is well versed to talk about the real hazards of working with live electricity and the need for quality PPE. After 43 years of working in this industry he explained: “I’ve never been exposed to an arc flash. Over the years I’ve seen electric arc and I’ve been close to one when we were on lines that were live and I’ve seen arcs a metre long. I think the correct kit now will make a difference to the people coming through now so they can protect their bodies against all risks. I think it’s a great thing that Northern Powergrid is investing money in kit for our safety.”

Conclusion

From the initial set up of the project through to the design modifications and the roll out of the new GORE-TEX PYRAD® jackets, salopettes and coveralls Northern Powergrid, Gore, J & K Ross, MSA Apparel and PHS have worked collaboratively with the focus on the end goal. The resulting fit for purpose waterproof and durable PPE provides Class 2 arc rated protection and lightweight wearer comfort for Northern Powergrid colleagues who work hard all year round on the front-line to provide high level service to its customers.

Sean Johnson, Safety Engineer at Northern Powergrid concludes: “Our teams work hard throughout the year to provide the high quality of service expected of them. They are exposed to the elements and the potential risk of heat, flame and thermal hazards associated with working with live electricity. Health and safety is our top priority and we have worked hard as an organisation to equip them with the durable, multi-norm Class 2 arc protection they deserve so they can remain focused on the task in hand and go home safe and well at the end of their shift.”

About Gore

W. L. Gore & Associates is a global materials science company dedicated to transforming industries and improving lives. Since 1958, Gore has solved complex technical challenges in demanding environments — from outer space to the world’s highest peaks to the inner workings of the human body. With more than 12,000 Associates and a strong, team-oriented culture, Gore generates annual revenues of $4.5 billion.